Shandong Jiayi Machinery Sheet Metal Equipment Manufacturing Base

+86 137-0538-4901 +86 189-5381-3118 |

sdjy@lag-rainer.com

Shandong Jiayi Machinery Sheet Metal Equipment Manufacturing Base

+86 137-0538-4901 +86 189-5381-3118 |

sdjy@lag-rainer.com

Product

产品展示

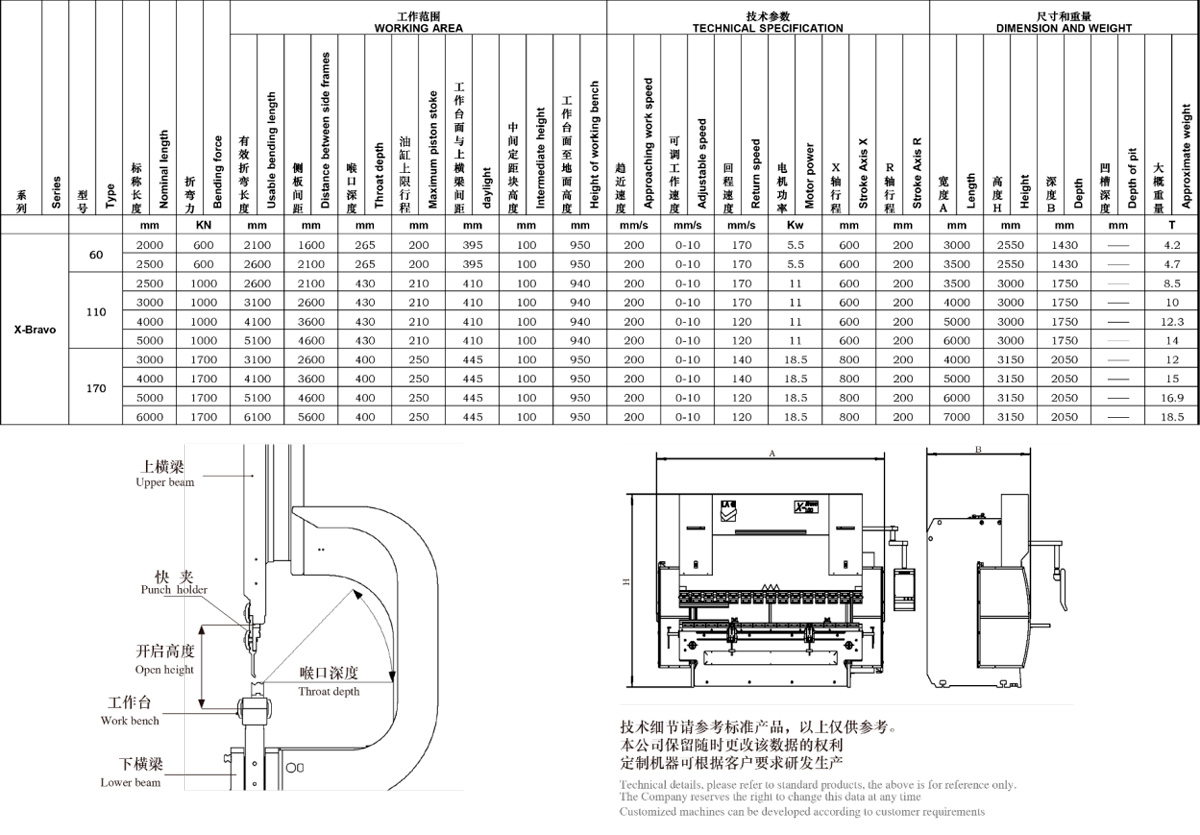

X-BRAVO Press brake

State-of the- art machine construction

A common feature to all X-Bravo series press brakes is a modular design platform, wealth of experience, modular machining bolted stable machine frame and the latest in control technology Unique, technological designed LAG heavy frame material S45C,weldding and stress fress improve the overall assembly accuracy and increase the working life.

G-FLEX

Patented frame proportional deflection compensation system

The G-Flex system guarantees consistency between each bend, in case the bending tonnage changes due to material characteristics such as strength, length or bending position on the press.

Typical of all press brakes, frame deflections are caused by the "C-shaped" side frames which open during bending causing what is called "yawning effect". This makes the upper beam position measurement erroneous if the linear encoders are directly fixed to the side frames. To prevent this reading error, the machine is equipped with "C-shaped" sub-frames bolted at the bottom of the lower beam and connected to the linear encoders. With this system the sub- frames are independent from the main structure and as such are not subject to the above mentioned deflection thus partly guaranteeing correct positioning of the machine.

With added G-Flex system, the actual position of the upper beam is measured by the two linear encoders installed on auto balanced lever on top of the "C-shaped" sub-frames. That mechanism does not follow any of the deformation of the frame during the bending therefore the measurement imprecision of the encoder caused by the yawning of the side frames is completely eliminated by the spring loaded mechanism.

X-CS

Self balancing and crowning system

This system compensates the deflections of the lower beam; it is synchronized with the G-Flex device; during bending phase, although lengths and positioning of parts varies, parallelism is still guaranteed. Programming or parameters are required by the operator throught CNC.

Back Gauge-synchronized axes (X-R)

Equipped with a standard 2-Axis (X-R) back gauge.

GRP-2 (X-R)

With a structure made from a precision aluminum extrusion and tubular steel beam combination, each axis has on each side have fully adjustable braces allowing a very precise fine-tuning of the parallelism and level of the fingers for maximum precision.

Highly integrated LAG's latest patented design is associated with X一R shafts fully sealed into a self-lubricated transmission, using straight line dual drive. This exclusive system supplies safe and reliable power transmission and perfect synchronization in driving left and right sides of each axis.

The unique design of LAG back gauge is attached very precisely and solidly to the side frames ofthe machine on dedicated machined surfaces for the high quality linear guides and gear rack transmission. This ensures perfect alignment of the back gauge structure with the side frame without any adjustment required.The rack transmission system uses a patented anti-backlash technology that allows the back gauge to reach speeds up to 600 mm/sec on the X-Axis.

Back gauge finger with anti-collision system

In case of collision, the fingers will be pushed off from the base, to avoid damaging the precision back gauge, and ensurebetter operator safety at the same time.

There are two fingers on standard machines, and it can be also equipped with extra fingers on request.

Manual sliding front supports

The front supports are sliding and manual to permit the movement belong the Z axe. The heigth of these front supports can be manually adjusted.

Punch Holder KYOKKO

Standard KYOKKO H=100 mm high precision manual quick clamping, compatible with European, Amada, Japanese and domestic type tools. One operator can quickly change and clamp vertically or from the side any upper tool. Optional versions available with double quick clamping or with H=150 mm.

Lower Tool Clamping G-Block M

Standard manualclamping

Quick change dies eliminate need to align punch and die when a die is changed;

Base is 60mm wide, allowing installation of standard European 4-V dies, T-dies, etc.

Modular tooling system

According to your required bending needs and the commonly used sheet thickness, LAG engineers, according to the open height and press brake can recommend the best selection, including:

standard. Punch 1 set

standard V-Die 1 set

The quick change base with T-shape 1 set

Customers can select other tools according to their needs

Safety·CE certification

The X-BRAVO press brakes with CE are equipped with the most advanced safety.

solution for press brakes in terms of productivity and safety protection.

In addition to the relevant standards and regulations to follow the installation complies with CE high- quality electrical and hydraulic components, such as the "DSP AP Laser Beam", electronic and hydraulic redundant systems guaranteeing safety without compromising the comfort of the operator. The DSP-AP laser safety device represents Its unique features and increases the competitiveness of the press brake.

Such safety devices are adjustable in height to simplify the tool extraction: further they are supplied with scale which are useful for the correct positioning of the laser beam in respect to the top tool.

Speed change 2 mm above material (0.2 sec)

Ø Allows the operator to work safely close tothe tools without interrupting highapproaching speed

Ø Tool crash protection

Ø Box mode to achieve complex shapes with no compromise to speed

Ø Fully integrated in the control; different operating modes selectable bend by bend (stop at mute-auto mute)

Ø Fast removal with automatic repositioning for lateral tool changing

Numerical control system

ESA 540 features:

Ø 10" TFT SVGA colour display with antiglare screen

Ø Interactive 2D graphic editor for work-pieces and tools data entry

Ø 2D graphic display of machine frame, work-piece and tools

Ø Manual 2D graphic identification of the best bending sequence

Ø Programming of the axes positions in tabular mode with automatic syntactical checks, automatic calculation of the R, Z and A positions and of the bending and crowning tonnage

Ø Windows. like user interface

Ø Preset for standard PC keyboard

Ø 2 USB port for memory stick

Ø Silicon hard disk (flash disk) for more than 30.000 part programs

Ø Standard 4+wila, on request up to 6+wila,crowning control

ESA630 features:

Ø 10" Touch Screen with powerful graphic

Ø All the performancesof a high-level cnc in an enconomical and userfriendly controller

Ø High-level graphic programming for easiness of use and soticated algorithms to make the most of your machine

Ø Direct management any kind of servo valves with no need of external amplifiers

Ø 4 axes

2D Off-line software

2D offline software is an easy-to-use and an effective tool for off-line programming of all X-BRAVO series press brakes

Main Standard Configuration

★Frame proportional deflection compensation system G-Reflex

★Traditional hydraulic crowning system X-CS

★CNC control mod. ESA540/Delem 58T

★4 +1 axis (Y1-Y2-X-R+C)

★Back gauge system mod. GRP-2(X-R)

★2 fingers on back gauge support

★CE standard

State-of the- art machine construction

A common feature to all X-Bravo series press brakes is a modular design platform, wealth of experience, modular machining bolted stable machine frame and the latest in control technology Unique, technological designed LAG heavy frame material S45C,weldding and stress fress improve the overall assembly accuracy and increase the working life.

G-FLEX

Patented frame proportional deflection compensation system

The G-Flex system guarantees consistency between each bend, in case the bending tonnage changes due to material characteristics such as strength, length or bending position on the press.

Typical of all press brakes, frame deflections are caused by the "C-shaped" side frames which open during bending causing what is called "yawning effect". This makes the upper beam position measurement erroneous if the linear encoders are directly fixed to the side frames. To prevent this reading error, the machine is equipped with "C-shaped" sub-frames bolted at the bottom of the lower beam and connected to the linear encoders. With this system the sub- frames are independent from the main structure and as such are not subject to the above mentioned deflection thus partly guaranteeing correct positioning of the machine.

With added G-Flex system, the actual position of the upper beam is measured by the two linear encoders installed on auto balanced lever on top of the "C-shaped" sub-frames. That mechanism does not follow any of the deformation of the frame during the bending therefore the measurement imprecision of the encoder caused by the yawning of the side frames is completely eliminated by the spring loaded mechanism.

X-CS

Self balancing and crowning system

This system compensates the deflections of the lower beam; it is synchronized with the G-Flex device; during bending phase, although lengths and positioning of parts varies, parallelism is still guaranteed. Programming or parameters are required by the operator throught CNC.

Back Gauge-synchronized axes (X-R)

Equipped with a standard 2-Axis (X-R) back gauge.

GRP-2 (X-R)

With a structure made from a precision aluminum extrusion and tubular steel beam combination, each axis has on each side have fully adjustable braces allowing a very precise fine-tuning of the parallelism and level of the fingers for maximum precision.

Highly integrated LAG's latest patented design is associated with X一R shafts fully sealed into a self-lubricated transmission, using straight line dual drive. This exclusive system supplies safe and reliable power transmission and perfect synchronization in driving left and right sides of each axis.

The unique design of LAG back gauge is attached very precisely and solidly to the side frames ofthe machine on dedicated machined surfaces for the high quality linear guides and gear rack transmission. This ensures perfect alignment of the back gauge structure with the side frame without any adjustment required.The rack transmission system uses a patented anti-backlash technology that allows the back gauge to reach speeds up to 600 mm/sec on the X-Axis.

Back gauge finger with anti-collision system

In case of collision, the fingers will be pushed off from the base, to avoid damaging the precision back gauge, and ensurebetter operator safety at the same time.

There are two fingers on standard machines, and it can be also equipped with extra fingers on request.

Manual sliding front supports

The front supports are sliding and manual to permit the movement belong the Z axe. The heigth of these front supports can be manually adjusted.

Punch Holder KYOKKO

Standard KYOKKO H=100 mm high precision manual quick clamping, compatible with European, Amada, Japanese and domestic type tools. One operator can quickly change and clamp vertically or from the side any upper tool. Optional versions available with double quick clamping or with H=150 mm.

Lower Tool Clamping G-Block M

Standard manualclamping

Quick change dies eliminate need to align punch and die when a die is changed;

Base is 60mm wide, allowing installation of standard European 4-V dies, T-dies, etc.

Modular tooling system

According to your required bending needs and the commonly used sheet thickness, LAG engineers, according to the open height and press brake can recommend the best selection, including:

standard. Punch 1 set

standard V-Die 1 set

The quick change base with T-shape 1 set

Customers can select other tools according to their needs

Safety·CE certification

The X-BRAVO press brakes with CE are equipped with the most advanced safety.

solution for press brakes in terms of productivity and safety protection.

In addition to the relevant standards and regulations to follow the installation complies with CE high- quality electrical and hydraulic components, such as the "DSP AP Laser Beam", electronic and hydraulic redundant systems guaranteeing safety without compromising the comfort of the operator. The DSP-AP laser safety device represents Its unique features and increases the competitiveness of the press brake.

Such safety devices are adjustable in height to simplify the tool extraction: further they are supplied with scale which are useful for the correct positioning of the laser beam in respect to the top tool.

Speed change 2 mm above material (0.2 sec)

Ø Allows the operator to work safely close tothe tools without interrupting highapproaching speed

Ø Tool crash protection

Ø Box mode to achieve complex shapes with no compromise to speed

Ø Fully integrated in the control; different operating modes selectable bend by bend (stop at mute-auto mute)

Ø Fast removal with automatic repositioning for lateral tool changing

Numerical control system

ESA 540 features:

Ø 10" TFT SVGA colour display with antiglare screen

Ø Interactive 2D graphic editor for work-pieces and tools data entry

Ø 2D graphic display of machine frame, work-piece and tools

Ø Manual 2D graphic identification of the best bending sequence

Ø Programming of the axes positions in tabular mode with automatic syntactical checks, automatic calculation of the R, Z and A positions and of the bending and crowning tonnage

Ø Windows. like user interface

Ø Preset for standard PC keyboard

Ø 2 USB port for memory stick

Ø Silicon hard disk (flash disk) for more than 30.000 part programs

Ø Standard 4+wila, on request up to 6+wila,crowning control

ESA630 features:

Ø 10" Touch Screen with powerful graphic

Ø All the performancesof a high-level cnc in an enconomical and userfriendly controller

Ø High-level graphic programming for easiness of use and soticated algorithms to make the most of your machine

Ø Direct management any kind of servo valves with no need of external amplifiers

Ø 4 axes

2D Off-line software

2D offline software is an easy-to-use and an effective tool for off-line programming of all X-BRAVO series press brakes

Main Standard Configuration

★Frame proportional deflection compensation system G-Reflex

★Traditional hydraulic crowning system X-CS

★CNC control mod. ESA540/Delem 58T

★4 +1 axis (Y1-Y2-X-R+C)

★Back gauge system mod. GRP-2(X-R)

★2 fingers on back gauge support

★CE standard

Telephonee:

+86 13705384901

Build Geshi international technology brand

CONTACT US

Tel:+86 13705384901 +86 18953813118 +86 0538-6089096 +86 0538-6089189

E-mail:sdjy@lag-rainer.com

Add:South of Kuixing Road, north of Xingfu Road, Ciyao Town, Ningyang County, Tai'an City, Shandong Province, China